Optimize your production processes with our deburring machines and achieve maximum precision and efficiency!

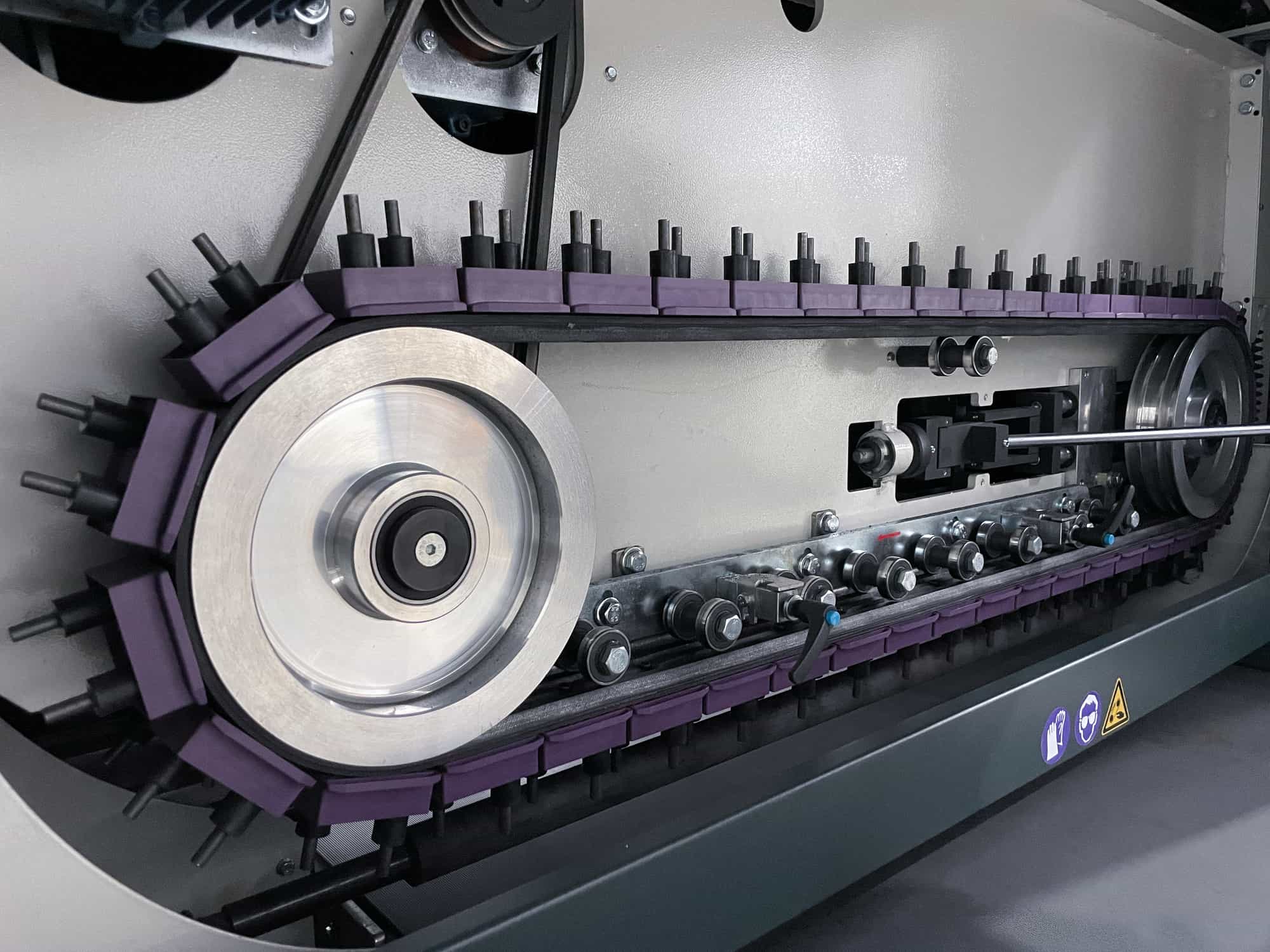

Our deburring machines ensure clean edges, improve surface quality and increase your process reliability. Thanks to high-quality components and innovative technology, they are versatile and can be almost completely automated.

Easy to operate, they offer numerous configuration options for processing a wide variety of workpieces. With high precision and reliability, they meet the requirements of modern production and sustainably increase productivity.

Simple edge rounding of sheet metal workpieces.

Deburring of laser, plasma & cut workpieces.

Edge rounding & deburring of laser, plasma & cut workpieces.

Remove slag from thick laser, plasma & cut workpieces.

André Pereira

Managing Director

Phone: +49 7267 45 198 11

E-mail: apereira@permatec.net

I look forward to your inquiry!

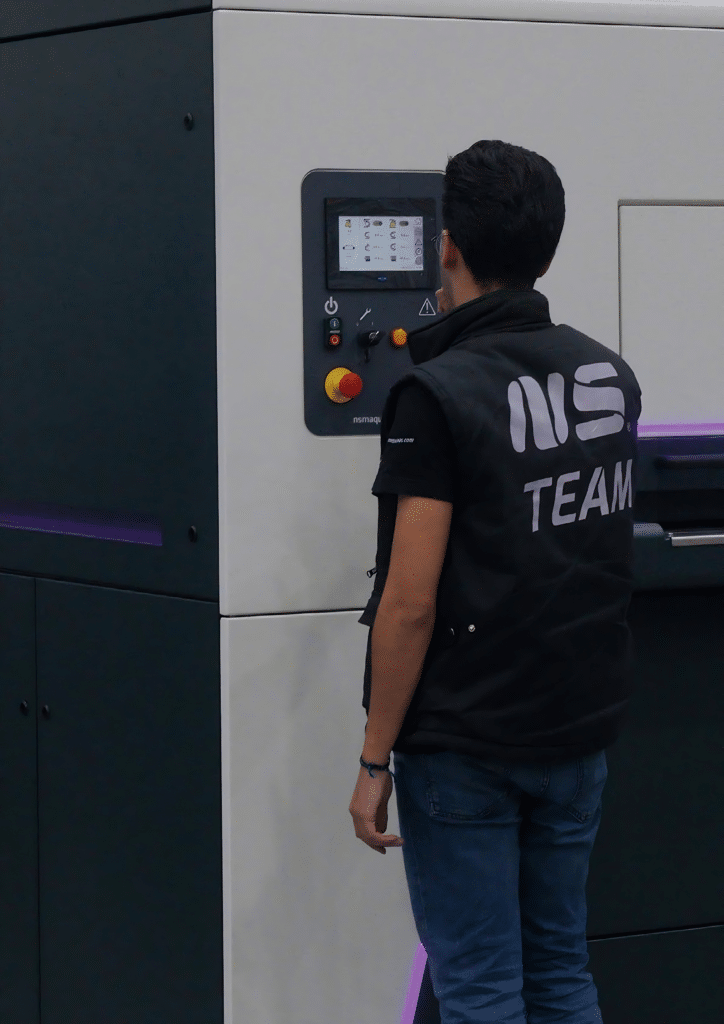

Automatic height adjustment: The deburring machines automatically adjust the working height to different material thicknesses; alternatively, the height can be set via the touch display. This saves time, reduces manual effort and ensures consistently good results.

Automatic wear compensation: The machines automatically compensate for brush wear. This means that the processing quality remains constant and manual readjustments are reduced.

Energy efficiency: With intelligent control systems, deburring machines only activate the main motors when a workpiece is detected. This reduces energy consumption by up to 30 %.

Less wear: The demand-based control of the motors reduces wear on important parts such as bearings, rubber rollers and V-belts. This extends the service life of the machine and reduces maintenance costs.

High precision: The deburring machines offer precise deburring and edge rounding results, ensuring that surfaces are processed evenly and to a high quality.

Simple operation: Thanks to modern control systems and intuitive displays, deburring machines are easy to operate and quick to set up for different tasks.

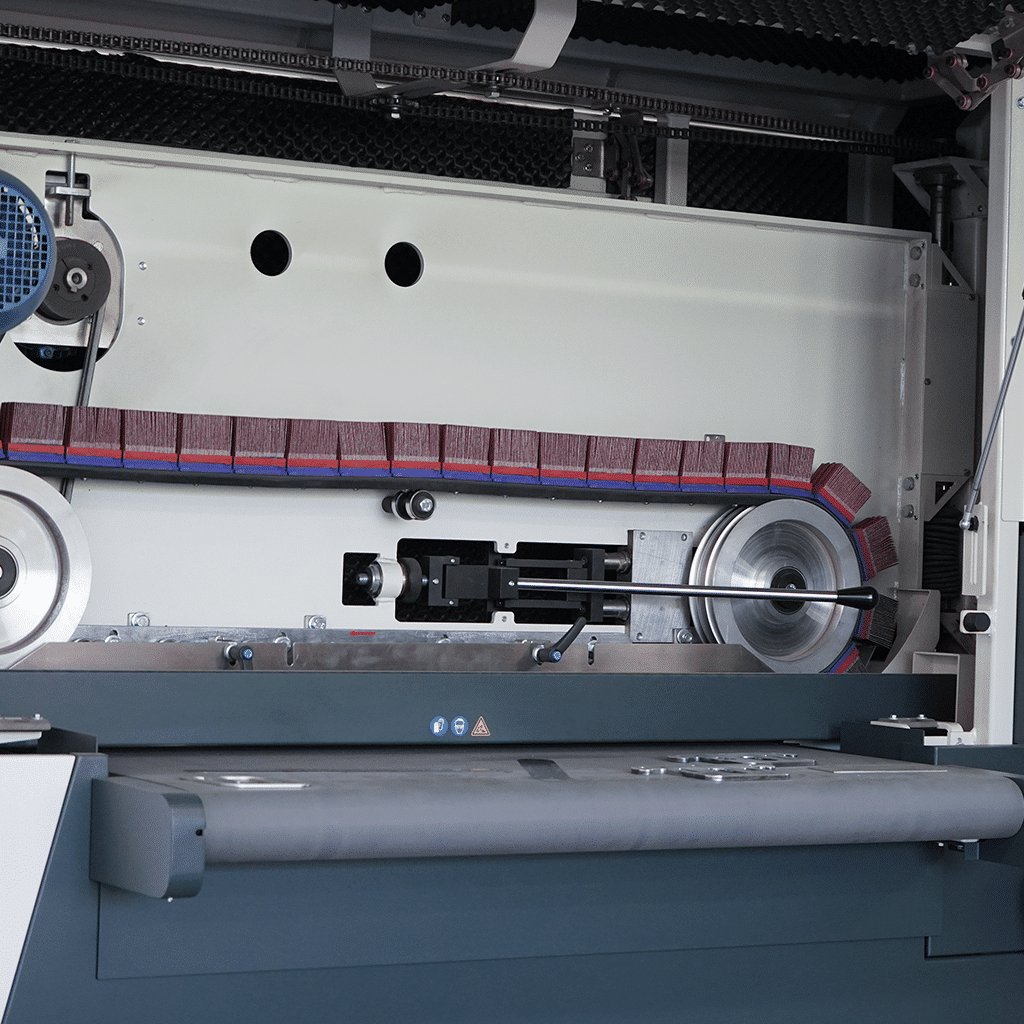

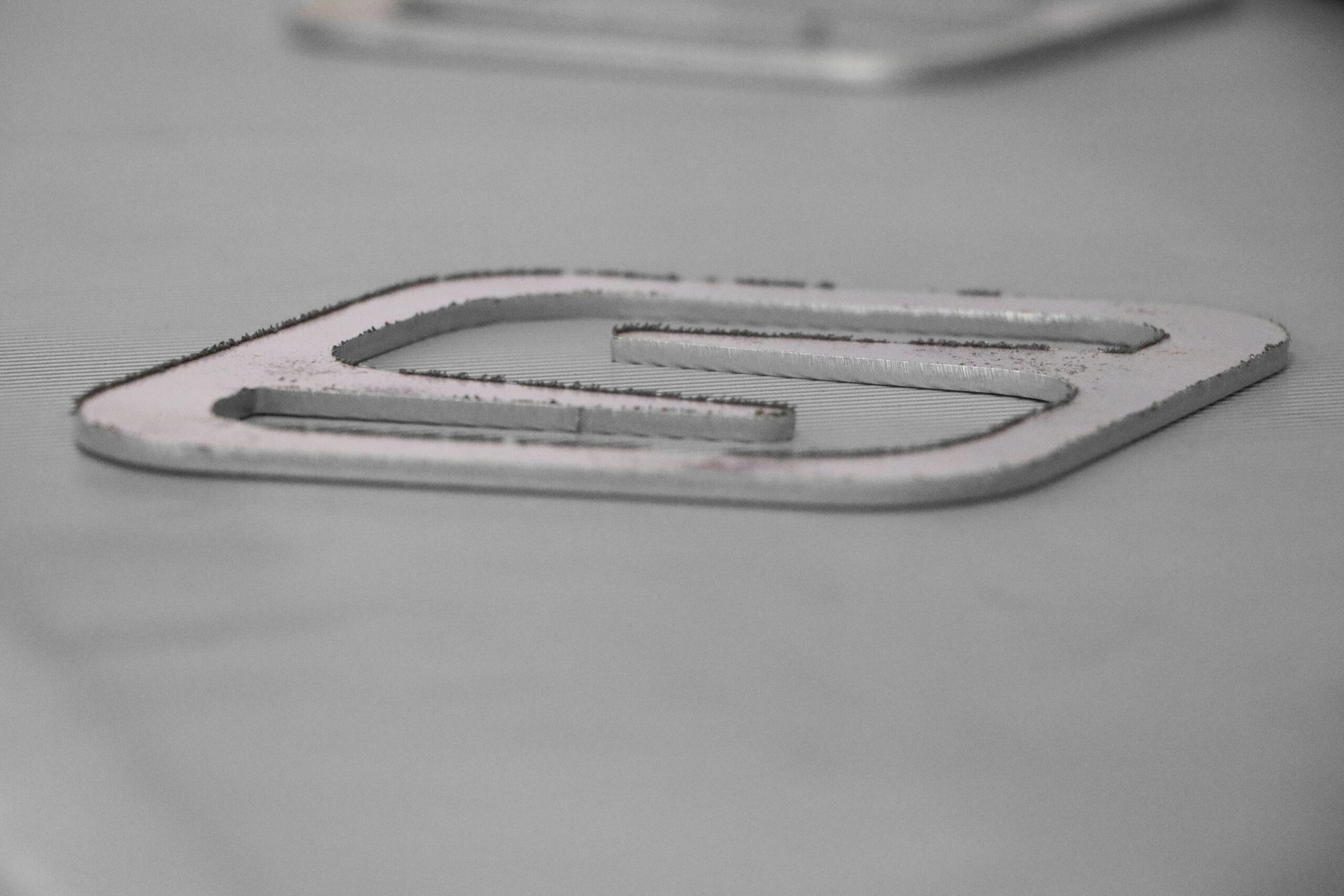

The “C” cross belt station of our sanding and deburring machines ensures effective and precise edge rounding of your workpieces. It is equipped with two counter-rotating brush belts that reliably deburr and perfectly round both the inside and outside edges of your workpieces.

The horizontal sanding belt station “Z” offers a powerful and precise solution for surface finishing and deburring. The

The contact drum station “D” is the ideal high-performance solution for surface processing and deburring. Thanks to the robust contact drum, even

Do you already have a concrete idea of your desired configuration?

Simply let us know your requirements and we will prepare a customized offer for you.

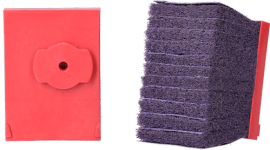

Remove slag easily with the impact hammer block with 55° firing pin.

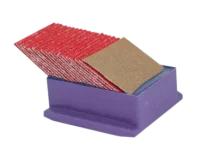

Strong rounding of your workpieces thanks to the 45° RED Angled Block.

Minimize costs and tool life with our quick-change deburring blocks.

No matter what requirements you place on your machine – our machines adapt flexibly to your conditions. With our innovative deburring tools, you can round off edges and efficiently remove slag and oxides. At the same time, you optimize the service life of your tools and reduce your costs. We offer you both standard abrasives for a wide range of materials as well as customized special solutions that are perfectly matched to your machine and the material to be processed.

in our showroom

A deburring machine is essential in sheet metal processing to remove burrs and sharp edges that occur during cutting, punching or laser cutting. This not only improves work safety, but also ensures a clean and high-quality surface.

Deburred sheet metal parts are easier to process further – whether for painting, coating or welding. In addition, a deburring machine ensures the precision and accuracy of fit of the parts, which prevents assembly problems.

Another advantage is the edge rounding, which improves the adhesion of coatings and increases corrosion protection. Visually enhanced components are particularly advantageous for visible end products.

Conclusion: The use of a deburring machine increases quality, safety and efficiency in sheet metal processing and contributes significantly to an optimized production process.

The use of a deburring machine is worthwhile as soon as the manual processing of sheet metal parts becomes time-consuming, imprecise or uneconomical. Companies that regularly cut, punch or laser sheet metal are often faced with the challenge of efficiently removing burrs and sharp edges.

Decisive factors for the use of a deburring machine:

Conclusion: A deburring machine pays off when higher efficiency, consistent quality and improved safety in operation are required. It optimizes production and quickly pays for itself as the order volume increases.

A deburring machine removes burrs and sharp edges from machined metal parts and ensures a smooth surface and precise edges. The machines from NS Máquinas work with different techniques:

The deburring process begins when the workpiece is fed into the machine. Conveyor belts move the part precisely through the various processing stations. Depending on the configuration and requirements, several sanding, brushing and roller stations can be combined to achieve optimum processing results.

Many deburring machines also have extraction systems that efficiently remove metal chips and dust. This ensures a clean working environment, greater occupational safety and protects the machines from soiling.

The modular machines from NS Máquinas offer flexible solutions for a wide range of requirements and ensure maximum efficiency and quality in sheet metal processing.

The deburring machines from NS Máquinas are versatile and suitable for processing a wide range of materials in the metal industry. Thanks to their flexible design and modern technologies, they offer optimum results for different surfaces and workpieces:

Our deburring machines are designed to adapt to the specific requirements of each material. Thanks to the combination of sanding belts, brush systems and roller stations, they achieve consistent, high-quality processing results – regardless of the material thickness and properties.

Professional advice before purchasing a deburring machine is crucial to ensure that the system is optimally tailored to your individual requirements. The right design depends heavily on the area of application in your company.

In addition, modern deburring machines offer numerous configuration options:

The deburring machines from NS Máquinas can also be equipped with innovative assistance systems. These minimize operating errors and ensure maximum precision and quality in the deburring process.