Increase the efficiency of your production processes by using our high-quality radial drilling machines and achieve outstanding precision!

Our radial drilling machines enable precise drilling, improve the quality of machining and increase the safety of your processes. Their robust design and innovative technology make them extremely versatile and ideal for a wide range of applications.

Thanks to their user-friendly operation, they offer numerous customization options for processing a wide range of workpieces. With their high accuracy and reliability, they meet the requirements of modern manufacturing and increase productivity in the long term.

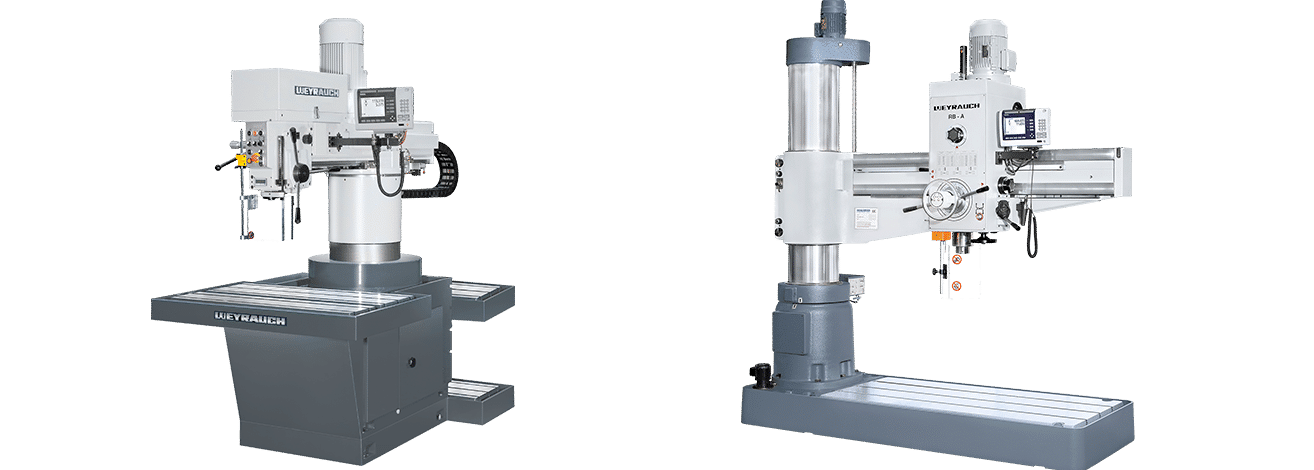

High-speed radial drilling machines for machining large workpieces in modern toolmaking.

Conventional radial drilling machines for machining large workpieces.

André Pereira

Managing Director

Phone: +49 7267 45 198 11

E-mail: apereira@permatec.net

I look forward to your inquiry!

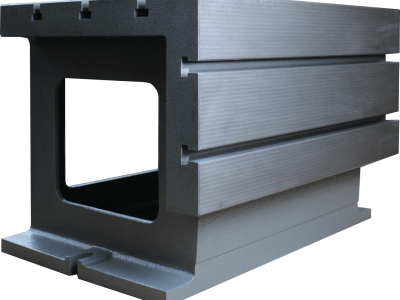

Our traditional radial drilling machines impress with their outstanding quality and consist entirely of durable gray cast iron bodies – naturally “Made in Germany”. Decades of experience in the design and manufacture of these precision machines enable us to create a product of the highest quality and reliability.

Our radial drilling machines are still indispensable, particularly in maintenance and toolmaking, where they are widely used. They stand for precision, robustness and a proven design that effortlessly meets the requirements of demanding applications.

Opt for a radial drilling machine that perfectly combines tradition, innovation and quality – a tool that will take your work to the next level.

Our high-speed radial drills set new standards in terms of user-friendliness and ergonomics. With a sophisticated design and state-of-the-art technology, they make working even easier and more convenient – perfectly tailored to practical requirements.

They are the ideal choice for training workshops in particular. Thanks to their intuitive operability and precise operation, they help trainee specialists to develop in-depth knowledge and skills in working with machines.

The robust design and high quality workmanship guarantee a long service life and reliability, even with intensive use. Choose our high-speed radial drilling machine to increase efficiency in your workshop and train the skilled workers of tomorrow.

Do you already have a concrete idea of your desired configuration?

Simply let us know your requirements and we will prepare a customized offer for you.

Our quick-change drill chucks allow you to change tools in seconds – quickly, easily and efficiently.

Our drilling tables can be equipped with your machine as required. We offer drilling tables with a clamping surface of up to 1200×1000.

Whether angle or swivel tables, we offer you the right solution for your machine.

No matter what challenges your workpieces or work processes entail – our radial drilling machines and the associated accessories such as clamping tables, angle tables and quick-change drill chucks offer maximum flexibility and adaptability. With precise accessories and reliable technology, they enable efficient machining processes. We also offer individual special solutions that are perfectly tailored to your requirements and the material to be processed. In this way, we guarantee maximum efficiency and quality for every application.

in our showroom

A radial drilling machine is an indispensable tool in metalworking, especially for the precise machining of large and heavy workpieces. Thanks to its swivel arm and movable drill head, it enables drilling, countersinking, reaming and tapping in hard-to-reach places.

The flexible extension arm allows the drilling head to be adjusted in various positions, which means that even complex drilling patterns can be realized. This is particularly advantageous when processing machine and system constructions as well as large housings.

The use of a radial drilling machine is worthwhile when large and difficult-to-access workpieces need to be machined precisely. This machine really comes into its own in companies with a high level of production diversity, where flexible and versatile drilling work is required.

Radial drilling machines are ideal if holes frequently need to be drilled at different angles and positions, as the swivel arm and movable drilling head offer a high degree of adaptability. From a certain workpiece size or for series production, the purchase can make economic sense, as these machines considerably reduce the time required and the need for reclamping operations.

Another advantage is its ability to deliver precise and repeatable results. In industries such as mechanical engineering, metal processing or plant construction, where accuracy of fit and efficiency are crucial, the radial drilling machine helps to optimize processes.

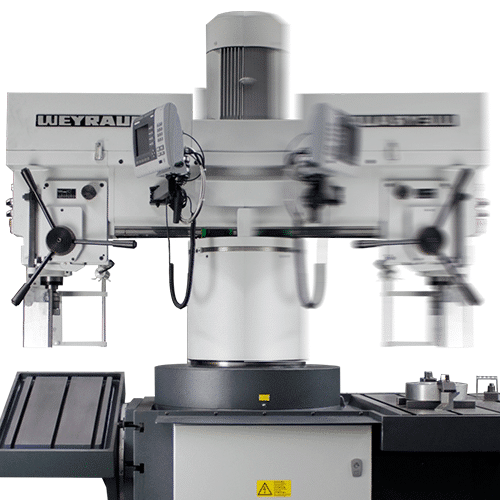

A radial drilling machine works by combining a movable drilling head, a swivel arm and a stable base, which together enable flexible and precise machining of large workpieces.

The central component is the boom arm, which is mounted on a vertical column and can be adjusted in height and rotated around the column. The drill head is attached to this arm and can be moved along the arm as well as tilted. This mobility makes it possible to drill holes at different points on the workpiece without having to move the workpiece itself.

The machine is controlled via a control panel, which can be used to position the drill head and adjust the spindle speed. The stable base or work table ensures that the workpiece remains securely fixed while the drilling process takes place. Thanks to the high stability and precision, other machining operations such as countersinking, reaming and thread cutting can also be carried out in addition to drilling.

When buying a radial drilling machine, there are several important factors to consider in order to find the right machine for your requirements. The size and power of the machine play a key role. Pay attention to the throat length, the maximum drilling diameter and the motor power to ensure that the machine can process your workpieces without any problems.

Flexibility and adjustment options are also crucial. A swivel arm, a height-adjustable work table and precise guides enable versatile and precise work. Stability is particularly important when processing large workpieces. A heavy base and solid construction ensure safe operation.

Furthermore, control and operability should be simple and intuitive. Automatic functions such as feeds or threading cycles can also make the work process easier. Also look out for safety features such as emergency stop switches and CE-compliant safety devices.

Our radial drilling machines and high-speed radial drilling machines are manufactured entirely in Germany, where, as the market leader, we focus on the highest quality and precision. The entire production process – from casting and machining to final assembly – takes place in our German production facilities. With over 50 years of experience since 1970, we have in-depth expertise in the design and manufacture of these machines. In 2014, we acquired the renowned Italian company BERGONZI, which enabled us to expand our product portfolio and further strengthen our market position and technical expertise.