DM 1100-2000 ZC

Deburring machine & Edge rounding machine

Deburring machine & Edge rounding machine

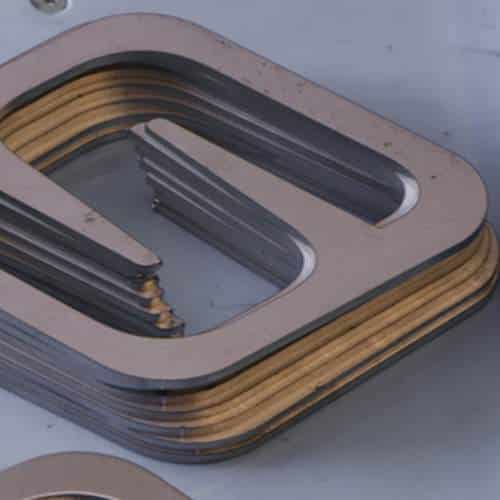

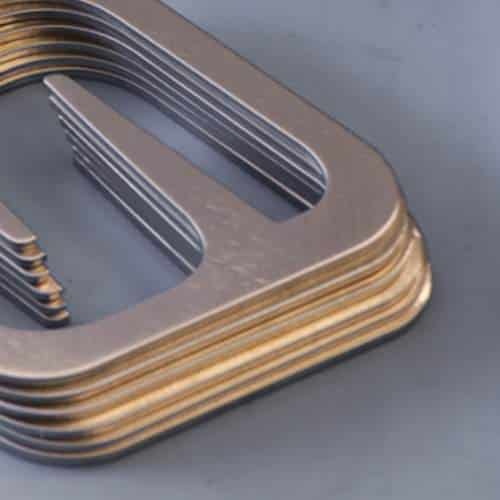

The DM1100-2000 ZC is the ideal solution for deburring & edge rounding of burrs & slag up to a working width of 1100 to 2000 mm.

This machine removes sharp edges on inner and outer contours and slag from stainless steel, steel or aluminum parts that have been cut using a laser, shearing or punching machine.

1100-2000 mm

Table width

120 mm

Max. Material thickness

Crossbelt straps +

Horziontal sanding belt

Deburring workpieces & rounding edges

The DM 1100-2000 ZC is extremely flexible thanks to its ability to process parts of different sizes – including those with a minimum size of 50 x 50 mm. With a sanding station (C) that has two cross-grinding belts running in opposite directions, it leaves clean, smooth and burr-free edges on all processed parts. The sanding station (Z) offers a smooth surface finish via a vertical load sanding station and removes slag and other irregularities from your workpieces.

The DM 1100-2000 ZC is extremely user-friendly and requires no special training. Operation is simple and intuitive. By turning the handwheel, operators can precisely adjust the height of the material, while another handwheel adjusts the height of the cross-belt sanding belts to achieve the desired surface finish.

If you are looking for a reliable, fast and simple edge rounding solution, the DM 1100-2000 ZC is the perfect choice for your requirements.

| Feature | DM 1100 ZC | DM 1600 ZC | DM 2000 ZC |

|---|---|---|---|

| Working capacity (mm) | 1100×120 | 1600×120 | 2000×120 |

| No. of belt stations (Z) | 1 | 1 | 1 |

| No. of crossband stations (C) | 1 | 1 | 1 |

| Sanding belt, dimensions (mm) | 1100×1850 | 1600×1850 | 2000×1850 |

| Sanding belt speed (m/s) | 8-22 | 8-22 | 8-22 |

| Cross belt speed (m/s) | 2-8 | 2-8 | 2-8 |

| Feed speed (m/s) | 0.6-10 | 0.6-10 | 0.6-10 |

| Conveyor belt motor per station (kW) | 11 | – | – |

| Total power (kW) | 18 | – | – |

| Suction connection per head (Ø mm) | (1x) 152 + (1x) 200 | (1x) 152 + (1x) 200 | (1x) 152 + (1x) 200 |

| Dimensions (mm) | 1880x2180x2080 | 2380x2180x2080 | – |

| Weight (kg) | 2050 | 2450 | – |

Deburring workpieces & rounding edges

The DM 1100-2000 ZC is extremely flexible thanks to its ability to process parts of different sizes – including those with a minimum size of 50 x 50 mm. With a sanding station (C) that has two cross-grinding belts running in opposite directions, it leaves clean, smooth and burr-free edges on all processed parts. The sanding station (Z) offers a smooth surface finish via a vertical load sanding station and removes slag and other irregularities from your workpieces.

The DM 1100-2000 ZC is extremely user-friendly and requires no special training. Operation is simple and intuitive. By turning the handwheel, operators can precisely adjust the height of the material, while another handwheel adjusts the height of the cross-belt sanding belts to achieve the desired surface finish.

If you are looking for a reliable, fast and simple edge rounding solution, the DM 1100-2000 ZC is the perfect choice for your requirements.

Interested in a sample?

We would be happy to send you a sample piece that has been machined on our DM 1100 ZC.

You can also send us one of your own workpieces, which we will machine according to your requirements.

Get started now! Optimize your production with our high-performance deburring machines.

Receive your free brochure!

Would you like to find out more about our high-quality tube grinding machines, deburring machines, metal band saws and drilling machines? Request our brochure now and discover how our solutions can optimize your production processes.

Fill out the form to download the brochure directly!