H1, H2 & H3

Forge furnaces

Forge furnaces

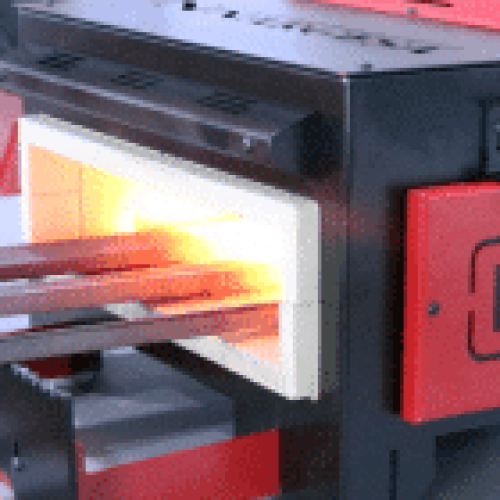

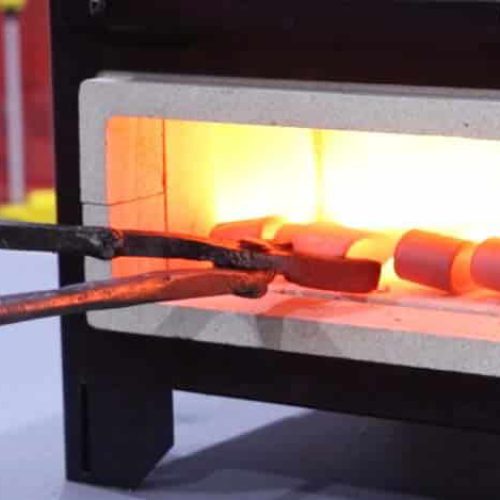

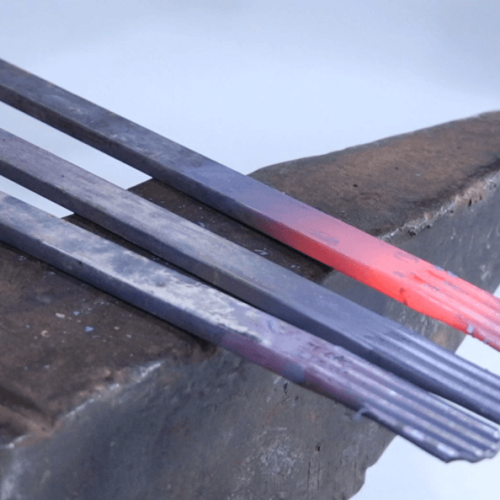

The Nargesa forging furnace series is ideal for heating metals. The furnaces are operated with propane gas.

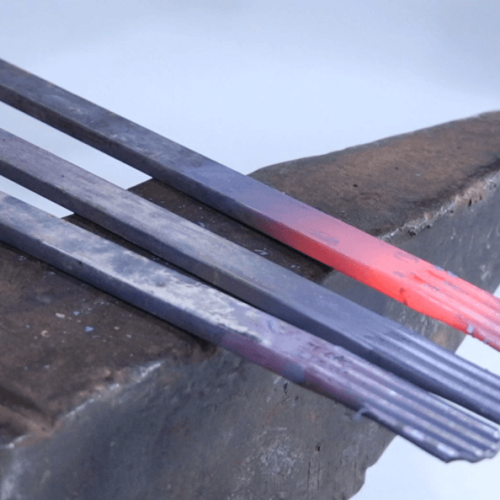

This makes them perfect for creative forging work such as forging tools or shaping metal objects.

Max. Operating temperature

1300°C

Burner

1-3 pieces

Propane gas

Modern technology & easy handling

Nargesa’s H1, H2 and H3 forging furnaces are ideal solutions for efficiently heating metal, such as iron, for forging and shaping. These furnaces offer state-of-the-art technology for artisan and artistic blacksmiths and operate on propane gas, using up to 75% less fuel than comparable furnaces. With a maximum operating temperature of 1300°C, they are perfect for forging, hardening, welding and working metals such as iron, steel and aluminum.

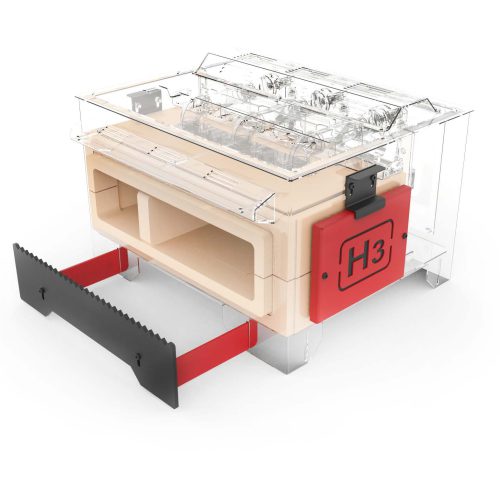

All models, whether H1 with one burner, H2 with two burners or H3 with three burners, have modern safety features such as automatic electronic ignition and non-return valves. This ensures a high level of safety during operation. The stoves are also particularly environmentally friendly thanks to their compact design and recyclable insulation material.

The flexibility of Nargesa ovens is particularly noteworthy: they allow workpieces to be processed through different openings and the burners can be operated independently of each other, which provides additional energy savings. These furnaces are ideal for use in the production of wrought iron work such as furniture, decorations and tools.

| H1 | H2 | H3 | |

|---|---|---|---|

| Max. Operating temperature (°C) | 1300 | 1300 | 1300 |

| Number of burners | 1 | 2 | 3 |

| Max. Consumption at 1 bar (kg/hour) | 0,35 | 0,7 | 1 |

| Combustion chamber bxhxt (mm) | 140x100x236 | 324x100x240 | 464x100x240 |

| Dimensions wxhxt (mm) | 450x370x310 | 440x370x500 | 580x370x510 |

Modern technology & easy handling

Nargesa’s H1, H2 and H3 forging furnaces are ideal solutions for efficiently heating metal, such as iron, for forging and shaping. These furnaces offer state-of-the-art technology for artisan and artistic blacksmiths and operate on propane gas, using up to 75% less fuel than comparable furnaces. With a maximum operating temperature of 1300°C, they are perfect for forging, hardening, welding and working metals such as iron, steel and aluminum.

All models, whether H1 with one burner, H2 with two burners or H3 with three burners, have modern safety features such as automatic electronic ignition and non-return valves. This ensures a high level of safety during operation. The stoves are also particularly environmentally friendly thanks to their compact design and recyclable insulation material.

The flexibility of Nargesa ovens is particularly noteworthy: they allow workpieces to be processed through different openings and the burners can be operated independently of each other, which provides additional energy savings. These furnaces are ideal for use in the production of wrought iron work such as furniture, decorations and tools.

Interested in a demonstration?

You are welcome to visit us or one of your customers to view the H1, H2 or H3 forging furnaces and test them with your workpieces. Simply make an enquiry now!

Get started now!

Optimize your production with our high-quality forging furnaces.

Receive your free brochure!

Would you like to find out more about our high-quality tube grinding machines, deburring machines, metal band saws and drilling machines? Request our brochure now and discover how our solutions can optimize your production processes.

Fill out the form to download the brochure directly!