Optimize your production processes with our tube grinding machines and achieve maximum precision and efficiency!

Our pipe grinding machines ensure perfect surfaces, precise contours and clean edge processing for pipes and round materials. Thanks to their innovative technology and robust design, they are versatile and guarantee consistently high quality.

The simple operation and numerous configuration options enable the processing of a wide range of pipe dimensions and materials. With precise grinding and high reliability, our machines meet the requirements of modern production processes and sustainably increase your productivity.

Easy grinding of pipes.

Wet grinding of pipes

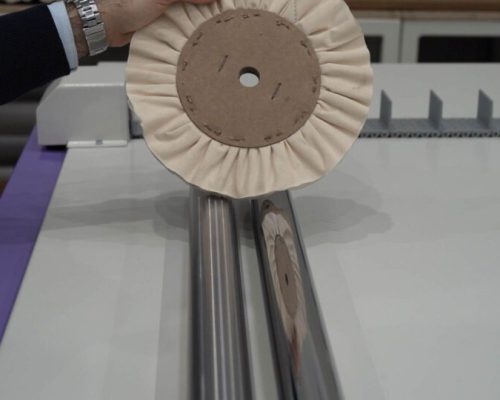

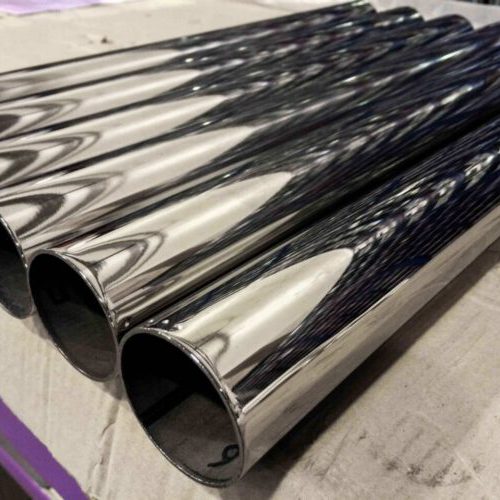

Rorhe polish & mirror polish.

Automated pipe grinding & polishing.

André Pereira

Managing Director

Phone: +49 7267 45 198 11

E-mail: apereira@permatec.net

I look forward to your inquiry!

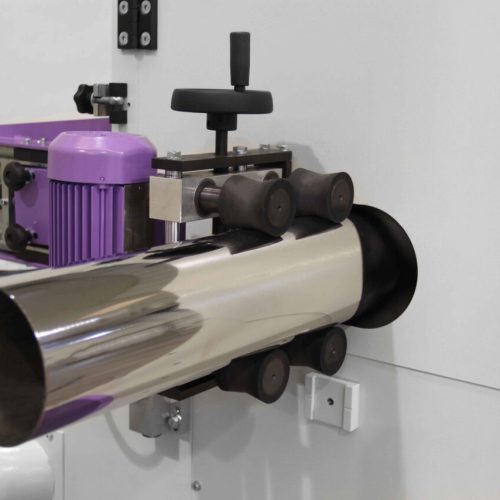

The specially developed planetary grinding technology from NS Máquinas enables precise grinding of both straight and curved pipes – without pipe rotation. The workpiece diameter can be set quickly and without tools using a quick clamping system. The tube is then simply and safely inserted manually into the grinding station – ideal for efficient one-off and series production.

The newly developed planetary polishing technology from NS Máquinas makes automated tube polishing even more efficient. Three

The ML / MLW Z series multi-sanding stations enable the integration of up to six individually configurable sanding modules in one line. This allows all processing steps – from pre-grinding to fine grinding and polishing – to be carried out in a single, continuous operation. This not only increases the processing speed, but also ensures reproducible results with consistently high quality.

Do you already have a concrete idea of your desired configuration?

Simply let us know your requirements and we will prepare a customized offer for you.

Abrasive cloth belts from grit 20 to 400 in various designs.

Coarse to very fine non-woven abrasive belts in various designs.

Polishing wheels and polishing soap in various designs.

No matter what requirements you have for your sanding application – we offer you abrasives that can be flexibly adapted to your needs. With our high-quality abrasive cloth belts in all grit sizes, non-woven abrasive belts such as Scotch-Brite, polishing discs and polishing soaps, you can process your workpieces efficiently and achieve perfect results. Our products are suitable for both standard applications and demanding special projects. Manufacturer-independent and of the highest quality, our abrasives support your processes, increase efficiency and ensure an optimum surface finish.

in our showroom

Tube grinding machines are used for processing, grinding and polishing tubes and cylindrical workpieces. They perform numerous tasks in various industries, including metalworking, furniture manufacturing and construction. The main applications include:

Surface treatment:

Deburring:

Preparation for coatings:

Tube forming and precision:

Cleaning:

Weld seam processing:

Pipe grinding machines are particularly advantageous as they adapt to the cylindrical shape of the workpieces and can deliver efficient, uniform results on long or curved pipes. They are often used in stainless steel processing, railing construction and industrial plants.

The use of a pipe grinding machine is worthwhile if certain requirements and conditions are met during operation. Here are some important aspects that indicate that its use makes sense:

Large quantities

If large quantities of pipes need to be processed regularly, a pipe grinding machine is more efficient and time-saving than manual processes.

Consistent surface quality

If a uniform surface finish or a specific finish is required (e.g. for stainless steel pipes), the machine offers significantly more precise results.

Complex geometries

For pipes with different diameters, bends or hard-to-reach areas, a specialized pipe grinding machine can achieve better results than manual processing.

Increasing productivity

If production is to be increased without compromising quality, the machine can optimize processes by automating machining.

Reduction in reworking

A pipe grinding machine can ensure that less reworking is required, which reduces labor and material costs.

Occupational safety and ergonomics

If manual processing is stressful due to noise, dust generation or ergonomic reasons, a pipe grinding machine improves working conditions.

Economic consideration

The use is worthwhile if the costs of purchasing, operating and maintaining the machine are justified by the increased efficiency and quality.

Examples of typical areas of application:

A pipe grinding machine is used to grind and polish pipes and round steel. It usually works with a system of abrasive belts that are guided by rollers. There are both stationary and hand-guided versions. In addition to grinding, a pipe grinding machine can also be used for satin finishing and polishing pipe constructions.

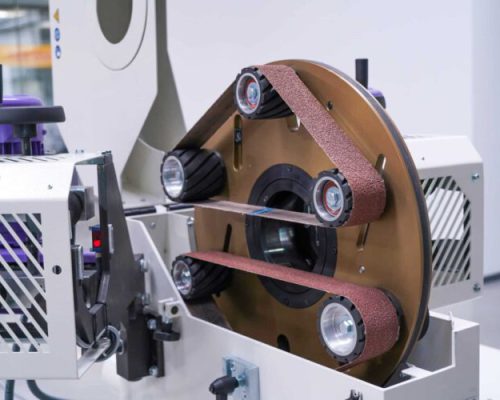

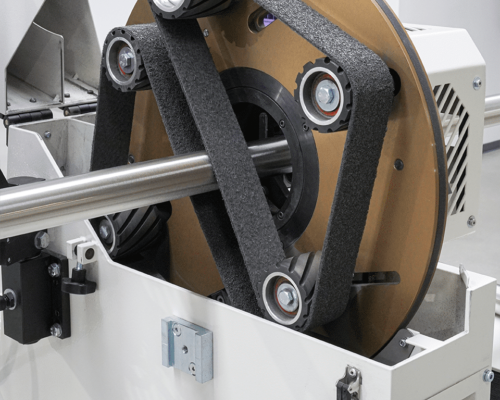

Some models, such as the ML100 from NS Máquinas, use a planetary sanding system. The sanding belts rotate around the pipe while it is being transported in a straight line, without the pipe itself rotating. This reduces the frictional heat on the surface of the pipe and enables even processing.

The operation of a sanding machine is generally based on the rotating or oscillating use of sanding tools that remove material from workpieces. This process is used to smooth surfaces, process edges or achieve certain shapes.

In summary, a pipe grinder works by using abrasive belts that rotate around the pipe and remove material to create a smooth and polished surface.

Our pipe grinding machines are suitable for a wide range of materials, including:

Thanks to the adaptability of our machines, they can be easily adjusted to the specific requirements of different materials to achieve optimum results.

The pipe grinding machines are manufactured by NS Máquinas near Porto in Portugal. The company develops and produces high-quality machines for grinding and polishing pipes and for metalworking. NS Máquinas has been offering quality machines in the areas of grinding, deburring & polishing for over 20 years.