FG 170/220/330

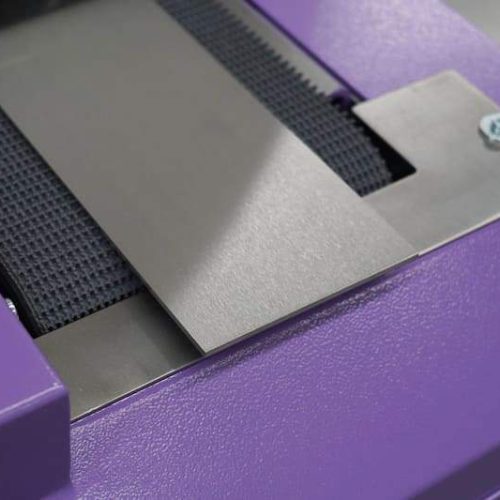

Continuous belt sander for profiles, bars & small parts

Continuous belt sander for profiles, bars & small parts

The FG 170, FG 220 and FG 330 continuous belt grinding machines offer a versatile solution for processing bar profiles, sections, bar stock and small parts. These machines can be equipped with two to eight sanding stations and enable both dry and water-cooled sanding.

With a processing width of 170 to 330 mm, they are ideal for achieving precise and efficient surface processing results.

up to 330 mm

Workpiece width

2-8

Grinding stations

water-cooled or dry

Loops

Individually equipped for a perfect surface finish

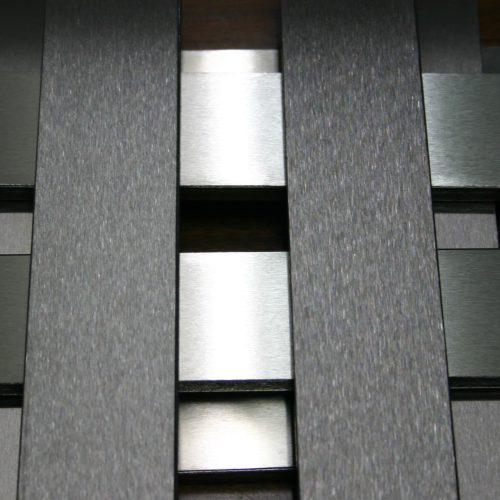

Thanks to their flexibility, the FG 170, FG 220 and FG 330 continuous belt sanding machines can process workpieces of different lengths and shapes. With up to eight sanding stations and a processing width of 170 to 330 mm, they enable precise sanding – dry or water-cooled – and are suitable for bar profiles, profiles, bar material and small parts.

The machines offer optimum surface quality and can be optionally equipped with a touch display or a control panel with push buttons. A filter unit for cooling water removes sanding dust and extends the service life of the machine.

The FG 170, FG 220 and FG 330 impress with their simple operation, versatility and burr-free, high-quality surfaces, regardless of the length or material of the workpieces.

| FG 170 | FG 220 | FG 330 | |

|---|---|---|---|

| Working capacity (Ø mm) | 170×200 | 220×200 | 330×200 |

| No. of belt stations (Z) | 1-8 | 2-8 | 2-8 |

| No. of brush stations (K) | 0-1 | 0-1 | 0-1 |

| Sanding belt, dimensions (mm) | 170×2000 | 220×2200 | 330×2200 |

| Brush strip dimensions (mm) | 170xØ200 | 220xØ200 | 330xØ200 |

| Water-cooled (W) | Optional | optional | Optional |

Individually equipped for a perfect surface finish

Thanks to their flexibility, the FG 170, FG 220 and FG 330 continuous belt sanding machines can process workpieces of different lengths and shapes. With up to eight sanding stations and a processing width of 170 to 330 mm, they enable precise sanding – dry or water-cooled – and are suitable for bar profiles, profiles, bar material and small parts.

The machines offer optimum surface quality and can be optionally equipped with a touch display or a control panel with push buttons. A filter unit for cooling water removes sanding dust and extends the service life of the machine.

The FG 170, FG 220 and FG 330 impress with their simple operation, versatility and burr-free, high-quality surfaces, regardless of the length or material of the workpieces.

Interested in a sample?

We would be happy to send you a sample piece that has been processed on our belt grinding machines. You can also send us one of your own workpieces, which we will process according to your wishes.

Get started now!

Optimize your production with our high-quality pipe grinding machines.

Receive your free brochure!

Would you like to find out more about our high-quality tube grinding machines, deburring machines, metal band saws and drilling machines? Request our brochure now and discover how our solutions can optimize your production processes.

Fill out the form to download the brochure directly!